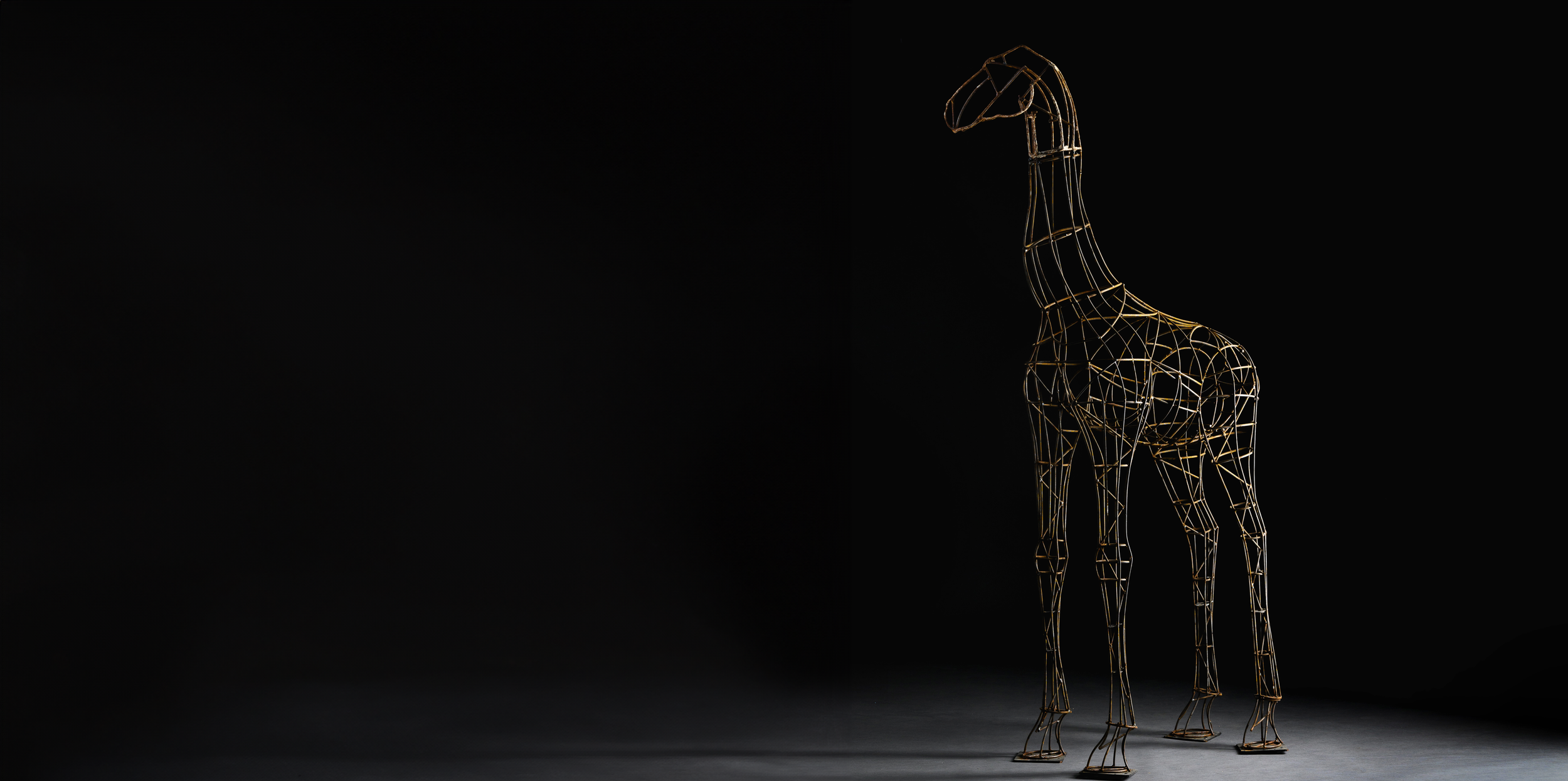

THE GIRAFFE

OVER 30,000 pcs.

STANDING

18’ Tall.

The Giraffe Project was a privately commissioned sculpture for the clients estate. The idea behind the sculptures was to create life-like giraffes from Stainless Steel for the clients 50th wedding anniversary. These structures contain thousands of stainless pieces that are cladded over the form of the giraffe. It was requested that the sculptures be realistic in size and form as well as light and ethereal; to not take away from the view of the estate.

The client’s wife had a deep love and appreciation for Giraffes. His goal was to find an artist to sculpt one 18’ Adult Giraffe and one 7’ Baby Giraffe. He nearly spent 8 months looking at 12 different artists in the Midwest area for any artist who fit the criteria. After multiple interviews DSIV was chosen for the project. At the time, this was the biggest / most challenging project he on. For the next 6 months he solely focused on building the Baby Giraffe and Adult Giraffe.

the process

One of the main reasons I was selected for the project was on the promise of my artistic style with stainless steel and obsession with the details. As you can see below, I use a steel frame technique to capture the true form of these giraffes. After the steel frame is finished, I roll, cut, and weld thousands of stainless steel pieces to small patterns then begin to use a stump - hammer technique to form each individual piece for it’s exact location on the sculpture.

For the heads of these sculptures, I use a reverse mold technique to create a dense pattern that is able to capture all the contours of a giraffes head. This is clearly one of my favorites parts of the sculpture. I prefer using this style for the most detail parts of my sculptures. The Giraffe head itself has so many unique shapes and curves, using the plain stump + hammer technique, you lose all the most distinct details.

After each individual piece is welded on the giraffe, I slowly cut the structure in half, remove the interior Steel frame, then gradually and meticulously put the stainless steel shell together. Once the shell is completely structural, I grind into the surface of the material, creating a flat surface that shines like a gem in the sunlight.